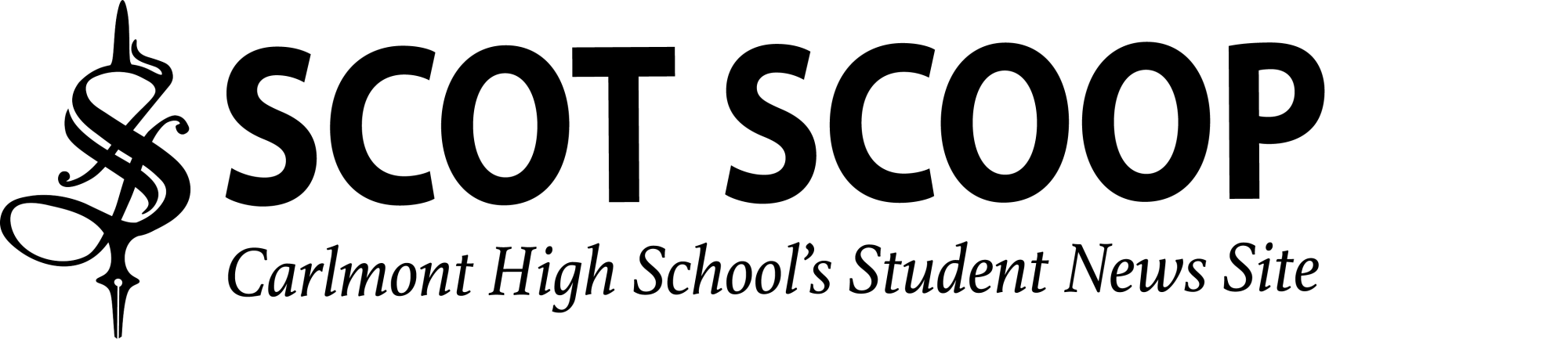

Deep Blue 199, Carlmont’s Robotics Team, is in the preparation period for their next competition at the end of November.

This year is the team’s third time competing at the Mechanical M-Ayhem Competition, where rookie members build and compete with a robot with guidance from experienced members.

“It’s like a normal competition, but much simpler, and we’re given less time for it because it’s focused on helping newer members learn the skills to create the robot,” said Nicholas Oey, the Carlmont Robotics Team president.

The rookie members learn Computer-aided design (CAD) skills to create a general template of what the robot will look like. This template also shows what components the robot uses, such as programming and fabrication to build prototypes and the final product.

Each competition has a game piece, with a goal each team must try to achieve. This year, the piece is a cube, and the teams must create a robot that will put the cube onto a shelf.

Deep Blue has two smaller teams, each with its individual designs. Team One’s design uses a ramp to tilt the cube onto the shelf, like a garbage truck.

“The design was really simple, and I had the veterans’ help,” said Eva Shen, a rookie designer. “I learned a bunch of new things, and it was really fun in general.”

However, there were a few things to take into account. According to Sequoia Leger, a Team One lead, the weight was too high and off to one side.

“The robot could tip over when we drive it,” Leger said. “We’re going to use ball bearings to add weight to the other side to balance it.”

Team Two’s design also has a ramp, but it will stay inclined instead of manually tilting it.

“They’re planning to have the robot go to a human source, and the human source will drop the cube onto it,” said Ethan Chan, a substitute lead. “Then, they’ll have a gate on the ramp to stop this cube from sliding off the robot and use a motor to open the gate and let the cube fall onto the shelf for points.”

According to Chan, Team Two has a good concept, but there are a few aspects to fix.

“A slight problem with the ramp is that it has a very high center of mass, so they’re either going to need to move very slowly or be extremely careful,” Chan said. “The CAD also has things that aren’t mated, which means that the objects simply float in the design; they’re not attached to anything.”

With this advice, the design rookies are fixing the CAD to ensure everything works.

The teams hope to finish their projects around Nov. 15, one week before the competition on Nov. 23, to allow driver practice.