Eco-friendly. Zero waste. Too often, people take these concepts for granted, adopting an “out of sight, out of mind” mentality regarding recycling. They fail to think about the impact their actions have on the environment.

Climate change, resource depletion, and overall recognition of our ecological footprint have gained more profound attention over the years.

These pressing problems have already started to impact Earth negatively as a majority of waste ends up in landfills, which carries polluting thing such as our water systems. Plastic is also found in the ocean.

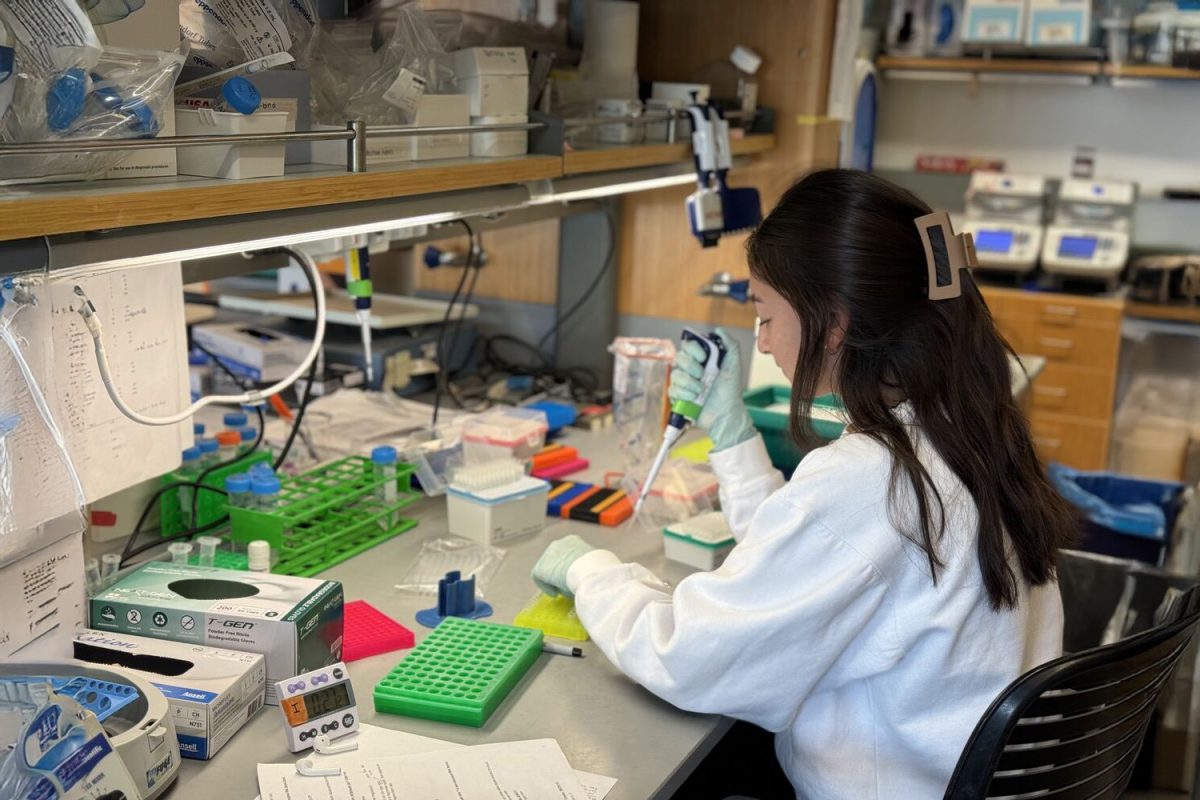

Implementing zero waste practices into daily routines reduces the human impact on our environment deeply. These can include things composting, using a reusable water bottle, and reusable bags.

“In my understanding, no material goes unused if you practice the concept of zero waste, “ said Heather Rockwood, Recology Waste Zero Specialist. “With compost, it’s a good way to get started because the food scraps can be placed in the compost, then they break down in 60-90 days, and are produced into future food, resulting in no waste.”

More businesses have been altering their goals to become more sustainable and eco-friendly.

Despite the efforts of some, the need for more waste management plants increases with the seemingly constant flow of waste created by humans.

What is an eco-friendly company?

Eco-friendly companies strive to minimize their negative outputs and prioritize the earth’s well-being. This includes practicing waste reduction, energy efficiency, green marketing, and ethical decisions.

Making ethical and responsible decisions plays a big part in labeling a company as eco-friendly. The law requires companies who label themselves “eco-friendly” and “green” to be transparent about their supply chain management and manufacturing process.

When a company is transparent, it builds a stronger relationship with its shareholders. It gains trust and reliability. People can see how sustainable and ethical the company truly is. Product labels and certifications are among the easiest things for consumers to verify the business’ credibility.

The B Corp certification is an important label for a company to have. It shows the company has committed to upholding strict environmental practices. The company has to prioritize the materials used and processes to make products rather than profit. To have this certification, the company has to pursue a social mission that will benefit the environment.

Canned Goods Clothing

Canned Goods Clothing is among many companies in the US that are striving toward sustainability.

Canned Goods is a clothing brand founded by 19-year-old Easton Dana. He runs the brand, selling primarily shirts packaged in aluminum cans, out of his dorm room and is fully committed to the sustainability of his company.

The defining feature of his company is that all of the products are packaged and shipped in aluminum cans. According to Dana, using aluminum instead of cardboard or plastic is much better for the environment because it can be used again.

“Unlike aluminum, plastic can’t be reused. It can’t be melted down and made into new plastic,” Dana said.

While he hopes that people will appreciate the aluminum packaging for being eco-friendly, Dana understands that not all consumers care about the sustainability of the products they buy.

“I made sure my product could hit targets of the market that don’t necessarily care about the sustainability aspect but do care about the collectability and uniqueness of the product,” Dana said.

He believes the packaging is unique enough in and of itself that people will buy it simply because it’s cool. It offers a different option for consumers rather than just plainly wrapped in plastic.

Even though aluminum packaging offers a more sustainable opportunity, it also requires a few extra measures. For example, his product must fit a large market because of the additional costs of aluminum packaging.

Aluminum cans are more expensive than cardboard or plastic. Also, the packing process is more complicated than traditional methods, so it takes more time, effort, and money.

Canned Goods has also committed to donate a portion of its profits to removing plastic waste from the ocean. For every shirt they sell, the money could go towards removing one pound of plastic.

Despite aluminum being almost infinitely recyclable, Dana does not see this material as the only path to the future of eco-friendly packaging.

“We’re advancing in new technologies every day, in terms of sustainable packaging, to the point where there might be something that comes out that’s more affordable than aluminum,” Dana said.

Recycling

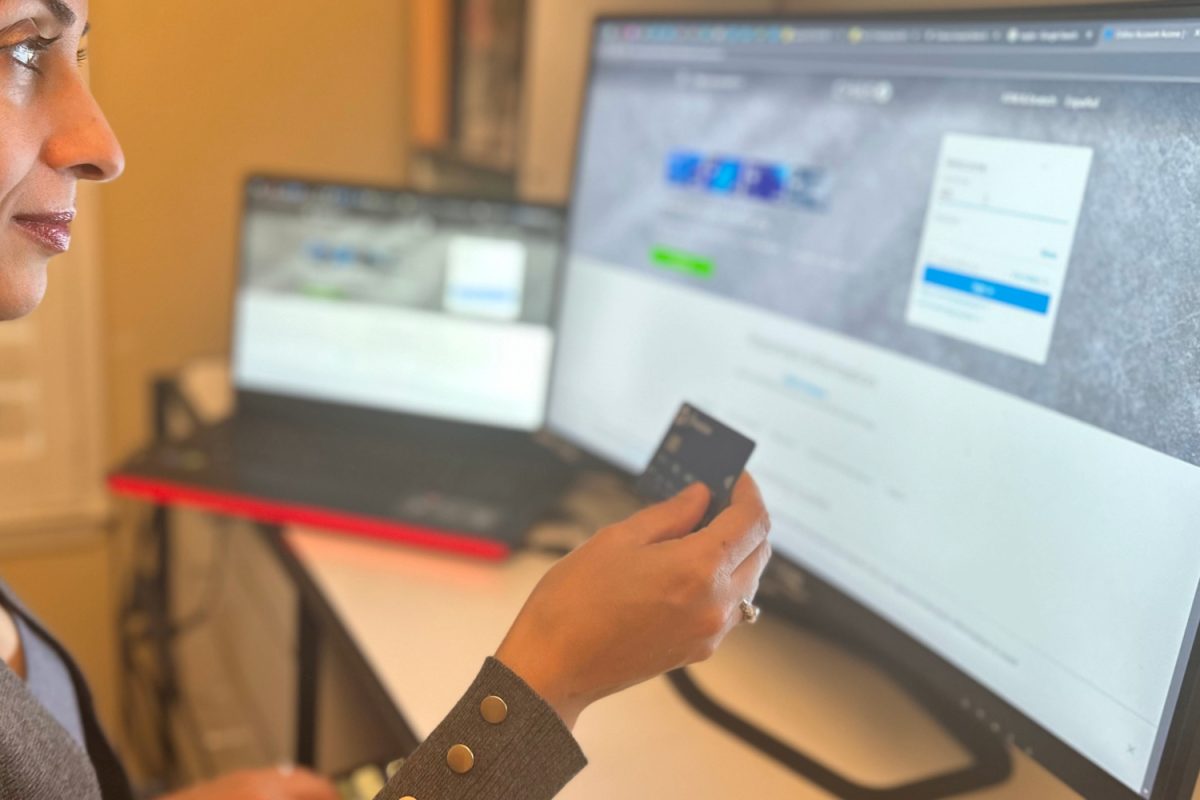

Humans commonly use plastic and aluminum, but their production and recycling processes could not be more different.

Most plastic is not recycled. Instead, it ends up in landfills or the ocean. 79% of all plastic on earth is in landfills, 12% has been incinerated, and only 9% has been recycled.

Of the small amount of plastic that is recycled, it is really downcycled, meaning it is used to make lower quality plastics than before.

There are many misconceptions regarding recycling.

“Another misconception, or something less known, is that glass is way better than plastic because it has a way longer shelf life, which is infinite compared to plastic,” said RethinkWaste Environmental Education Team Member, Alexandra Edwards.

Another common misconception is small plastics, like Ziploc bags and plastic forks, can be recycled. However, advanced recycling of plastics involves melting plastics into more basic products, not turning them into other plastics.

Since plastic is difficult to recycle, companies would rather produce more plastic than recycle old plastic. Since plastic is made from oil, this leads to the continued depletion of Earth’s limited oil supply, which will run out in the next 54 years, according to the MET Group.

Aluminum is the opposite of plastic: easy to recycle and hard to produce. Aluminum can be melted and poured into molds to make infinitely new products. Very little is lost in this process, making aluminum recycling very efficient.

Because its recycling process is so simple, it is way cheaper than producing new aluminum, which requires extracting the metal from aluminum ore.

“75% of the aluminum we have today is from the original aluminum when it became widely popular,” Rockwood said. “That other 25% we’re missing, it’s in landfills because we’re throwing it away.”

Using more aluminum instead of plastic benefits the environment because of its recyclability and long-term sustainability, helping the planer work towards a greener future.